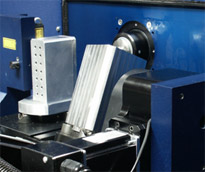

G4-ULTRA CNC

MicroMachining Centers

______Standard Configurations |

|---|

Three X, Y, Z axes. |

______Maximum Table Load |

|---|

5 lbs (2.73 kg); Higher payload, as special. |

______Servo Spindles |

|---|

100,000 RPM Servo air cooled spindle as standard, |

______Speed and Acceleration |

|---|

Acc/Decs XYZ of >2 G’s; Speed maximum of 30 m/min. |

______Accuracy |

|---|

XYZ 0.6 µm to position, ~2 micron along path (dynamic). |

______Resolution |

|---|

XYZ 0.1 µm all axes individually. |

______Repeatability |

|---|

XYZ 0.3 µm to position, ~1 micron along path (dynamic). |

______Automatic Tool Changer |

|---|

(# of tools) Fourteen tools per cartridge; With additional cartridges and/or part fixtures, (14) new tools input < 30 seconds. |

______Tool Position Repeatability |

|---|

Validation of tool tip depth within one micron |

______Conductive Contact Probing |

|---|

(Standard) Contact probing within one micron. |

______Travel |

|---|

X___101 mm (4 inch) work envelop Y___101 mm (4 inch) work envelop Z___76 mm (3 inch) stroke. 101 mm (4 inch) work envelop w/ table rotation.. |

______File Format |

|---|

G code program storage in .txt files. CAM option programs semi-auto generated from SolidWorks, ACAD, STEP files. |

______User Interface |

|---|

Macro capabilities User interface for manual, program call and G-code programs. Macros for planarizing, surface probing, tool change, part shifts, peck drilling, etc. |

______Major Options |

|---|

Table options for 3, 4, or 5 axes, 200k RPM spindle, CAM software, |

______Non Contact Confocal Laser |

|---|

Probe option for non-conducting and translucent/transparent materials. Automatic deployment. Accuracy < 1 micron. G code supported. |

______Coolant System |

|---|

Flood and directed recirculated filtered coolant, G-code directed. |

Office or Factory

Standard G-Code program

110 VAC and 4 Bar air

100k-200k RPM Spindles

Standard Conductive Probing

Non Contact Confocal Laser

Flood & Mist Coolant System

__

__

3 Axis _________________ 4 Axis

5 Axis